Forneau de recuit de précision à bande de verre optique de type courroie à mailles

| Utilisation de l'équipement |

Pour les bouteilles en verre, les ustensiles en verre et autres ustensiles et les bouteilles en verre pour les cosmétiques, etc.

Pour le verre d'éclairage, le verre quotidien, le verre de pressage (cold annealing)

|

| Température maximale |

750 °C |

| Température normale |

500 à 600 °C |

| Longueur du four |

18M à 36M |

| Taille du four |

Largeur 300mm-2500mm, hauteur 120mm-350mm (peut être personnalisé selon le client) |

| Vitesse de fonctionnement |

0 ~ 500 mm / min (réglable en continu) |

| Largeur de la ceinture à mailles |

300 mm à 2500 mm |

| Matériau de bande |

SUS304, SUS321 en acier inoxydable |

| Point de contrôle de la température |

5 ~ 20 points |

| Mode de régulation de la température |

Contrôle indépendant sous-régional |

| Précision de la température de commande de l'instrument |

± 1 °C |

| Température uniforme dans le four |

≤ ± 5 °C |

| Chauffage |

Pièces de chauffage électrique à base de quartz |

| Système de régulation de la température |

Système de contrôle de température intelligent PID, interface de contrôle à écran tactile |

| Caractéristiques |

1La précision de la température dans le four est précise, l'homogénéité de la température du four est élevée et la consistance du produit est bonne.

2, Le fonctionnement de l'équipement du dispositif de tension de la courroie pneumatique à mailles est stable.

3, toute la fibre de céramique chauffant la structure de la plaque de coton, la hausse rapide de la température, l'économie d'énergie est efficace.

|

| Les commentaires |

Les paramètres ci-dessus sont uniquement pour référence, cet équipement est un équipement non standard, qui est personnalisé en fonction des exigences réelles du processus du produit. |

L'utilisation de l'équipement de traitement des eaux usées est interdite.

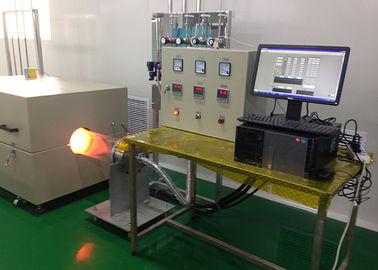

1, Vue d' ensemble du produit

Ce lehr est principalement utilisé pour les bouteilles en verre de vin, les ustensiles en verre, le verre quotidien et le verre procédé, la décoration de marque à haute température (papier coloré) et la décoration en or;la longueur totale du four est de 28 à 40 mètres; la température maximale d'utilisation est de 650°C; et il convient à la production continue de grands lots.

2, Tableau des attributs de paramètres

1Longueur de la ligne: 10 à 32 m

2- Puissance de démarrage: 30-270 kW/380 V

3Métode de transfert: 304/321 ceintures en maille en acier inoxydable, régulation de la vitesse de conversion de fréquence.

4Largeur de la ceinture à mailles: 300-4000 mm

5Température maximale d'utilisation: 750°C

6. précision de régulation de la température: ± 1°C

7Mode de commande: système de commande intelligent PID, commande multipoint.

8Circulation d'air chaud: la largeur de la bande de maillage ≥ 1,2 m peut être prise en compte par circulation d'air chaud

9Structure de l'entreprise: modulaire; assemblage sur place

3, Utilisation du produit

- Équipement sur mesure non standard, principalement utilisé pour les ustensiles en verre d'usage quotidien tels que les bouteilles en verre, les tasses en verre et autres produits en verre pour la décoration à haute et basse température (encre en verre à haute température,papier à dessin)

- Peut également être utilisé pour: le verre d'usage quotidien, le verre pressé, le verre d'éclairage et tout autre traitement thermique par recuit à froid et à chaud.

4, Caractéristiques générales

Le procédé de production consiste à placer le produit sur la courroie à mailles, entraîné par la courroie à mailles, et à le chauffer de l'extrémité d'alimentation dans le four, à travers l'ouverture du four pour former,ensuite refroidi progressivement par la chambre de refroidissement, puis recueillies par l'extrémité de décharge pour compléter l'ensemble du traitement thermique.

S'il vous plaît contactez-nous pour plus de détails, nous allons faire sur mesure pour vous!

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!  Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!