Le Four industriel à verre est au cœur de la fabrication moderne du verre, alimentant les industries qui fournissent des matériaux de construction, des composants automobiles, de la verrerie domestique, du verre photovoltaïque et des conteneurs industriels. Alors que la demande mondiale de verre de haute qualité continue d'augmenter, comprendre le fonctionnement d'un four industriel à verre est devenu essentiel pour les fabricants et les professionnels de l'industrie.

Un four industriel à verre est conçu pour faire fondre des matières premières telles que le sable de silice, la soude, la dolomie et le calcin à des températures supérieures à 1 500 °C. Les fours avancés utilisent des systèmes de chauffage régénératifs ou récupératifs pour maintenir des conditions de fusion stables et réduire la consommation de carburant. L'objectif principal du four est d'assurer une fusion, un affinage et une homogénéisation uniformes du verre en fusion avant le formage.

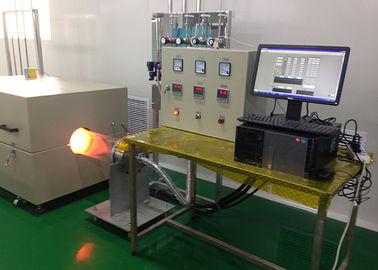

Une caractéristique clé d'un four industriel à verre est son contrôle supérieur de la température. Les brûleurs de haute technologie, la combustion oxygène-carburant et les capteurs de surveillance intelligents permettent aux usines de maintenir une répartition uniforme de la chaleur, réduisant ainsi les défauts tels que les bulles, les stries ou les inclusions dans le produit en verre final. Ceci est crucial pour les secteurs exigeant une clarté optique supérieure, tels que la production de panneaux solaires et le vitrage automobile.

Un autre avantage est l'efficacité énergétique. Les fours industriels à verre modernes intègrent des chambres de récupération de chaleur qui recyclent la chaleur des gaz d'échappement, réduisant considérablement les coûts de carburant. Avec l'augmentation des réglementations en matière de fabrication à forte intensité énergétique, les entreprises se tournent vers les brûleurs à faibles émissions de NOx et les fours hybrides à suralimentation électrique pour réduire l'impact environnemental.

Les fours industriels à verre sont également construits pour la durabilité. Les matériaux réfractaires qui tapissent l'intérieur du four doivent résister à des températures extrêmes et aux réactions chimiques. Les réfractaires de nouvelle génération prolongent la durée de vie du four tout en maintenant la stabilité structurelle.

Les industries qui dépendent de ces fours comprennent les usines de verre flotté, les usines de verre pour conteneurs, les fabricants de verre borosilicaté et les producteurs de verre spécialisé. Alors que les normes environnementales se resserrent, la demande de technologies de fours plus efficaces et respectueuses de l'environnement continue de croître.

En résumé, le Four industriel à verre joue un rôle essentiel dans la production mondiale de verre, offrant une grande efficacité de fusion, un fonctionnement stable et une excellente qualité de produit. Avec les innovations continues dans les systèmes de combustion et la surveillance numérique, l'avenir de la fabrication du verre s'oriente vers des solutions de fours plus propres, plus intelligentes et plus économes en énergie.

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!  Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!